Embroidery Machine Thread Breaking & Shredding: 10 Fixes

This post may contain affiliate links, which means I’ll receive a commission if you purchase through my links, at no extra cost to you. I sometimes receive free products for review. Please read disclosure for more information.

I despise when my embroidery machine thread keeps breaking in the middle of a project when I’m on a strict deadline.

Whether it’s late at night or I’m in a rush to finish something, my machine often has a mind of its own, and that’s when things start going wrong.

Luckily, I have a sequence of steps for troubleshooting embroidery machine thread breaking and shredding that I’ll share.

Then, you’ll know where to look and how to fix this unfortunate embroidery machine problem!

Why Does Embroidery Thread Break or Shed?

Anything that impedes the free flow of the top or bottom embroidery thread can cause thread breaks.

Same with incorrect threading or set up of your embroidery machine.

Add in problems caused by supply selection (stabilizers, needles, threads, and more), and you now have a small selection of the reasons that embroidery thread shreds or breaks.

Troubleshooting Embroidery Machine Thread Breaking Or Shredding

If you can determine where the shredding or breaking occurs (around the top tension discs, at the spool, at the eye of the needle, below the needle plate, etc.), troubleshooting is simpler.

If you have no idea about the location, try pausing the machine and advancing the design stitch by stitch using the handwheel. Watch closely and observe where the problem starts. This slow-mo stitching has saved me several times!

Still stumped? Below are possible causes of thread breakage and how to fix them.

I’ll start first with the upper thread breaking and then move on to the sporadic cases when your bobbin thread is breaking on an embroidery machine.

1. Change Needles.

If your needle has a burr or is dull or bent, it can cause issues with your thread.

To rule out needle issues, switch to a new needle. Make sure the needle is inserted all the way up with the flat part facing back. (If your needle threader also isn’t working, poor needle insertion is a likely culprit.)

Also, always ensure you are using the right size and type of needle for your embroidery project. While a 75/11 embroidery needle is a decent start for most projects, it’s not always the best choice.

If, for instance, you’re running a very thick thread (or specialty thread) through a needle with a small eye, the friction from the machine’s quick stitching can cause the thread to shred at the needle as it passes through the too-small hole.

In this case, choose a needle with a larger, elongated eye hole, like a topstitching needle or metallic needle. These needles’ eyes, shafts, and scarves have special characteristics to prevent machine embroidery thread from stripping, skipping, and breaking.

If you’re lost regarding needle selection, I recommend Deborah Jones’ Embroiderer’s Compass (above), which suggests needle and stabilizer choices for many fabric types.

2. Change Thread and Check Feeding.

Are you using metallic thread, which is notorious for shredding those annoying little metal coils in your upper tension discs?

If so, check out these tips for embroidering with metallic thread. In addition to a specialized needle, metallic threads also require a lower tension to prevent thread shedding at the tension discs and special attention to how the thread feeds.

Now, if you are only using regular embroidery thread, go ahead and try a different brand or color of thread to see if the problem temporarily resolves. If it does, it might mean your machine doesn’t love a particular brand or type of thread.

Old and poor-quality threads sometimes can’t withstand the stitching speed of modern embroidery machines and can snap easily.

Also, make sure your thread is set up for smooth feeding.

If thread pools along the bottom of the spool or is twisted as it comes off the spool, the thread can get caught and break. Consider a thread net to help with better feeding and decrease thread pooling.

My common culprits for breakage in the upper thread path are when my thread wraps around one of the thread guides on my thread holder or the thread gets caught around the spool pin under the spool cap.

In this case, I’m 100% guaranteed a thread break and possibly an embroidery needle break, too.

And lastly, if your thread is horizontally fed, try feeding it vertically (or vice versa) to keep it from twisting as it enters the top tension mechanism. You can also try using a thread stand if you have your thread in your machine.

3. Check the Top Thread Path.

If thread catches anywhere in the machine top, it can break at (or before) the needle.

Or, if the tension discs or upper thread path are dirty and have thread remnants in them, the slight extra tension exerted on the thread can be enough to wreak havoc.

The bobbin thread might start showing on the top of the embroidery, the thread may begin to shred before finally breaking, and the needle may not even pick up the bobbin thread reliably.

To troubleshoot the upper thread path, rethread your machine with the presser foot UP, and clean the top thread path.

Use a brush where you can, and run a piece of UNWAXED dental floss through the path as if you were threading the machine.

Also, make sure you are threading the needle from front to back and pulling the top thread tail out of the eye.

The needle threaders on my Brother embroidery machines often make a thread loop at the eye of the needle, and I have to manually situate the thread correctly before starting to stitch. If I don’t, I risk thread shreds.

Also, a few times my embroidery presser foot has been too high, causing thread shedding. If your machine allows you to adjust presser foot height, you can do this as another troubleshooting step.

4. Check Needle Plate for Burrs or Nicks.

Any imperfections near the needle hole of the throat plate (outside OR inside) can cause issues with the threads interlocking as they should. This can lead to shredding and breaking.

Slight imperfections can be polished or buffed out with a file or sandpaper. Larger ones may require a replacement needle plate.

5. Check the Bobbin Area.

If your bobbin thread is breaking on your embroidery machine, the problem may be with your bobbin. Of course, the bobbin area can also contribute to upper embroidery thread breaks.

I always have several new bobbin cases and fresh bobbins on hand when troubleshooting embroidery machine thread breaks.

To rule out bobbin problems causing thread breaks:

- Clean out the bobbin case (remove the bobbin) and underneath the bobbin case (remove the bobbin case, and you’ll likely see thread fuzz and small thread pieces.)

- Inspect the bobbin, bobbin case, and hook for scratches or imperfections. Over time, these can get old and nicked.

- Use the correct bobbin for your machine, the correct bobbin case for your machine and bobbin type (read your manual), and make sure to orient the bobbin in the correct direction.

- Use machine embroidery bobbin thread, not sewing thread or regular machine embroidery thread in the bobbin.

- If you are using pre-wound bobbins, switch to a bobbin you wind yourself to rule out a bad batch of bobbins.

- Check that the bobbin thread tail is not getting caught under the needle plate by taking one stitch and holding the upper thread. Use the upper thread to pull the bobbin thread up out of the needle area.

For Brother embroidery machines, the bobbin thread must also pass through the tension spring before connecting with the top thread if you want to get good-quality stitches.

6. Switch Designs.

Not everyone is a star digitizer, and sometimes too many needle penetrations in a small area can cause issues with your embroidery machine.

Change to a different design (or a different design section) and see if you still have issues.

You can minimize issues from a poorly digitized design by using a thinner thread at the problem spots and avoiding metallic threads.

7. Thread Spot #6 Correctly on Brother Embroidery Machines.

For thread breaking on Brother embroidery machines, check the position of thread guide #6. It’s a flimsy piece of metal that can get out of place easily on newer Brother machines.

Ensure it is above the needle clamp as it should be. (The picture above shows the proper orientation.) If not, you should be able to move it back with a pair of sharp tweezers or your favorite maintenance tool.

When troubleshooting thread breaking on my Brother SE1900 embroidery, I once tried EVERYTHING before realizing this was the culprit.

8. Decrease Upper Thread Tension.

If the top tension is too high (more likely to be caused by thread impeded in the thread path rather than the disc tension value), you can try decreasing the tension on the upper thread.

This is helpful for specialty embroidery threads but shouldn’t be something you do regularly when experiencing problems.

9. Inspect Hooping.

Make sure you hoop fabric taut and use the correct stabilizer for your fabric. Loosely hooped projects can pucker, shift, and cause thread messes, leading to thread breakages.

If you’re floating your project and it’s not stable, consider hooping or at least using a basting box or spray adhesive for stability.

Also, if you’re using a ridiculous amount of stabilizer on a thick fabric, this is a potential problem.

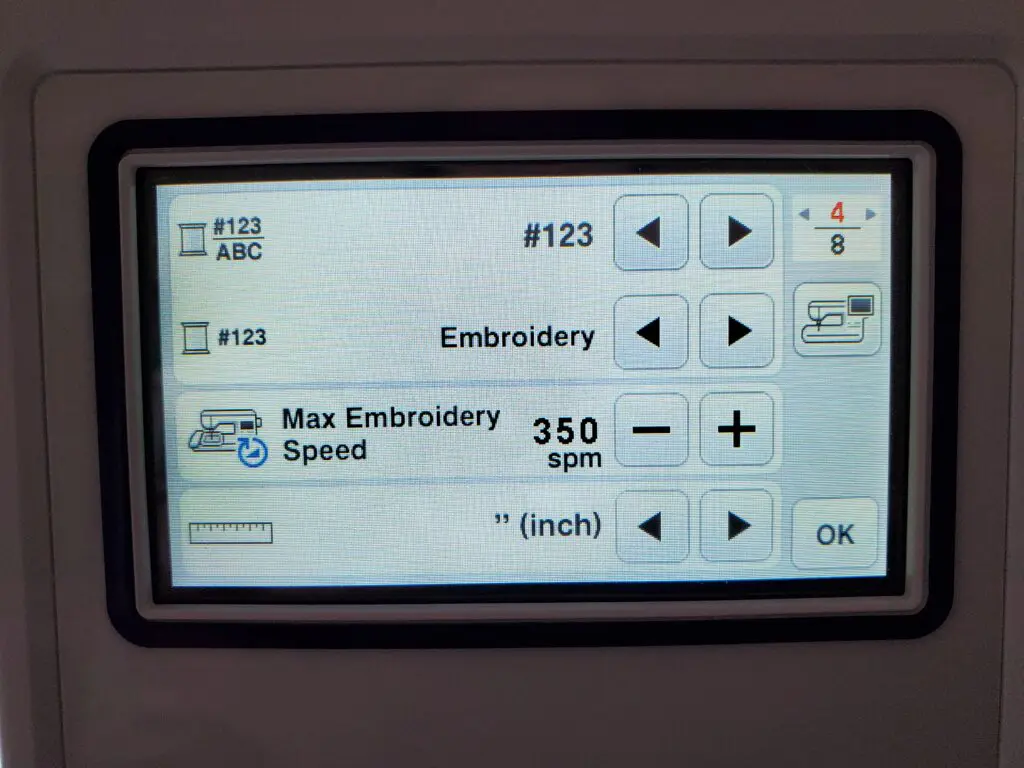

10. Decrease Machine Speed.

While not likely to fix a thread shredding issue unless your problem is shredding metallic thread coils, decreasing speed embroidery speed helps you catch errors earlier when troubleshooting.

Worse Case Scenario: Maintenance Time

If these troubleshooting steps don’t stop embroidery thread shredding and breaking, it might be time for embroidery machine servicing.

It’s possible your timing is out of whack or something else inside your machine is not working as it should.

Your local authorized dealer should be able to spot and fix any problems.

Embroidering Over Embroidery Mistakes

If your thread breaking causes notable design flaws, you can easily embroider over areas of your design again.

Simply back up your embroidery machine using the touchscreen interface, and start stitching again.

If you’ve already unhooped, you can return with your sewing machine or a needle and thread and patch up those areas.

Final Notes

I hope these machine embroidery troubleshooting steps for thread catching, breaking, and shredding on an embroidery machine have helped you resolve your issues!

Please let me know anything else you’ve found that causes such problems.

I really love the help and comment, I learned a lot that I did not know before from threading ,thread breaking thread and needle sizes etc. I guess it doesn’t matter how experience you are in sewing there is always something you learn from the peoples experiences. Thank you, It is great knowing all this things.

Thelma,

Thanks, I’m glad this was a helpful resource!

This is invaluable information. Thank you so much. Although I’ve been embroidering for several years I’m still a beginner and information such as this is welcomed. Thanks again

Thanks for the information about the embroidery machine I really appreciated this information

Please I have a problems with my embroidery machines and I need solutions to it,these are the problems;my machine does not stops when the down thread breaks.

Secondly one of my machines usually stops while it is working when the stop button had not been pressed. Thank you

What brand and model embroidery machines do you have?

Thank you so much! It’s been 9 months since I had my machine serviced, so I couldn’t figure out why the thread was breaking as it wasn’t the tension. Well, it was your #7 tip which I would have never figured out on my own. Much appreciated!!!

I’m glad you figured out your problem! I had that same issue and was so frustrated until I realized what the problem was finally!

Bookmarking this as it seems I have this problem more and more and I forget all the things to check 😀 — this has been VERY HELPFUL, THANKS!!!